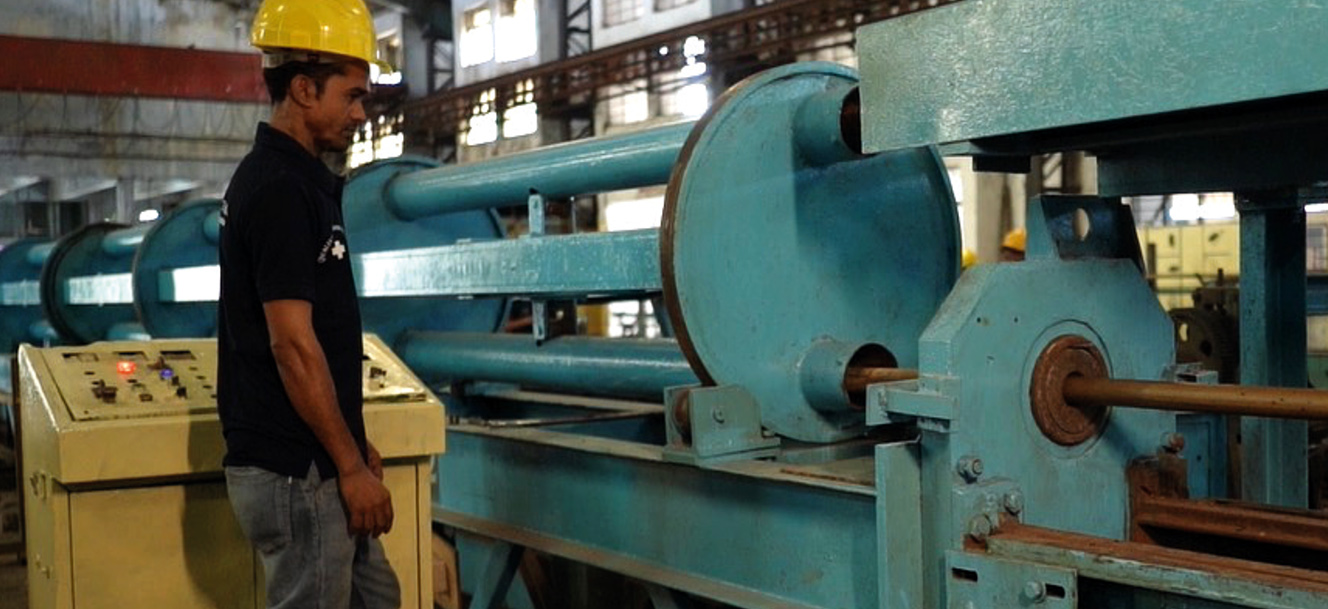

HMTL has a dedicated plant of 27,500 sq. mtr. of covered area for manufacturing cold drawn of Stainless Steel Seamless & Welded Tubes/pipes with 15 pilger mills, bright annealing furnace, 5 Draw benches, 3 tube mills etc.

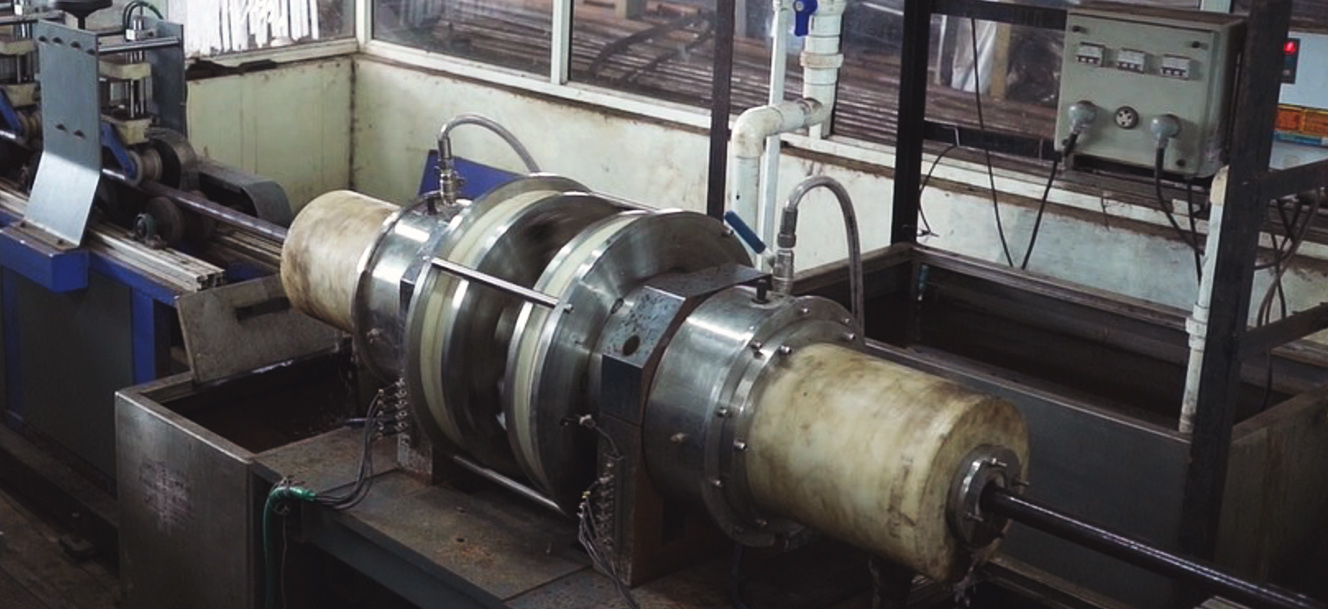

Cold finished Tubes / Pipes are produced out of quality seamless hollows which are manufactured in house or procured from reputed mills. Seamless hollows are either cold pilgered over pilger mills or cold drawn over draw benches using precision tooling (dies & plugs) to achieve perfect dimensions and smooth surfaces.

Pilgered / Drawn tubes are subjected to heat treatment, straightening and surface treatment. Finished tubes / pipes undergo various testing as per the specification /customer's requirements followed by marking and packing.

| PRODUCTS |

|

|---|---|

| MANUFACTURING RANGE |

|

| GRADE & SPECIFICATIONS |

|

| CAPACITY |

|

Round Bar

Hot Finish Hollow

Preparation

Hollows / Mother Tubes

Drawing / Pilgering

Surface Treatment

Straightening

Heat Treatment

Surface Treatment

Cutting

Physical Chemical & Mockup Test

Non-Destructive Test

Destructive Test

Hydro Testing

Heat Treatment of U Bend Portion (If required)

Degreasing

U Bending

(if required)

Final Cutting

Surface Treatment

Visual & Dimension Inspection

Marking, Packing & Dispatch