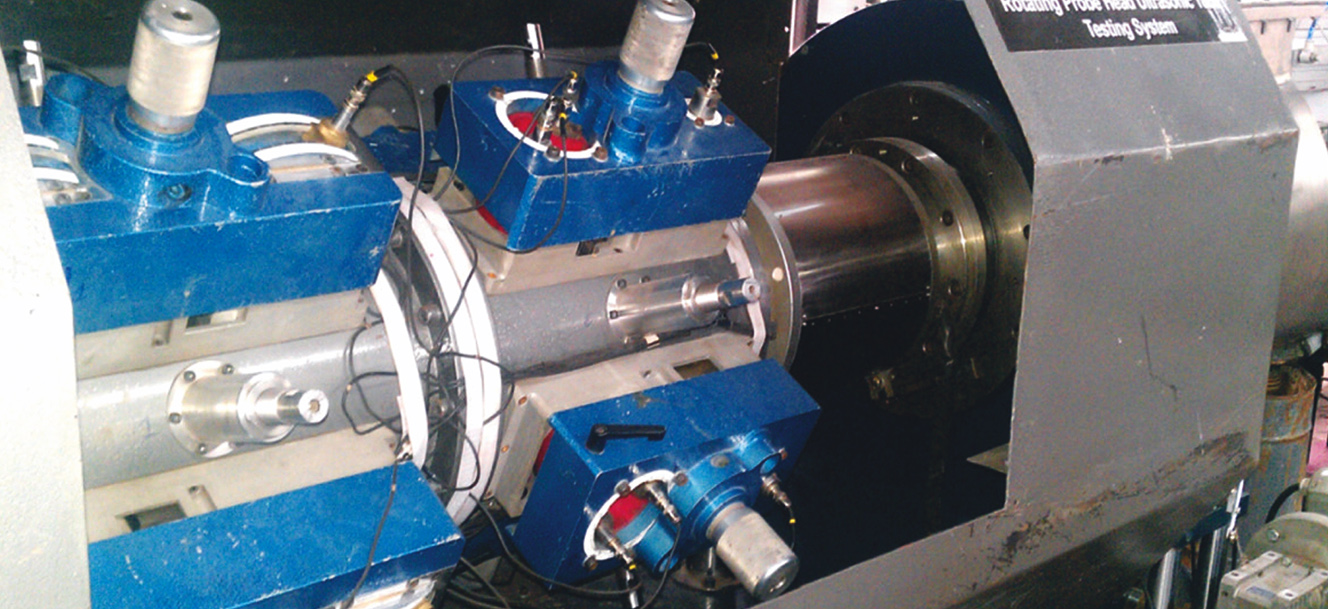

Ultrasonic Testing

If asked by the customer, pipes are subjected to Ultrasonic testing. An acoustic transmitter probe generates a sound beam which is applied to test piece using water as Couplant. The Ultrasonic Test Equipment is calibrated using a reference test piece with artificial defect test which is from the same pipe lot that is to be tested. The tested tubes are considered flawless if they do not cause any indications longer than that produce by the reference test piece. The Ultrasonic Test is conducted as described in ASTM E 213/A-450.

Non - Destructive Testing Machine

| Sr. | Ultrasonic | 3 Rotating Probe Method | 1 Scanner (Upto 8") |

|---|---|---|---|

| 1 | Channels | 10 Channels | 10 Channels |

| 2 | Longitudal Defect | 4 Probes | 4 Probes |

| 3 | Transverse Defect | 4 Probes | 4 Probes |

| 4 | Wall Thickness | 1 Probe | 1 Probe |

| 5 | OD & ID | 1 Probe | 1 Probe |

| 6 | Speed of Testing | Upto 20 Meters per Minute | Upto 20 Meters per Minute |

| 7 | Notch Depth | 5% of Wall Thickness | 5% of Wall Thickness |

Eddy Current Test

This test is used to detect hidden flaws, inhomogeneties, cracks etc. using the test procedure described in ASTM E-426. Tecnofour Flaw Mark detector with digital data recorder is used for testing entire length of the tubes.

Hydrostatic Tests

All tubes and pipes produced at HMTIPL are compulsorily subjected to 100% hydro testing. Hydrostatic Testing can be carried out at pressures upto 450kg /cm sq. Customers or their deputed inspection agencies can witness 100% hydro testing at our plant. For thin wall tubes Pneumatic Testing (Air under water) is done at 300 psi max. Air pressure.