The flaring test serves to establish the forming behavior of tubes or pipes which is

expanded to a specific degree. This flaring test is carried out in conformity with the

code requirements. The specimen to be tested is expanded in a press to the degree

specified. Defects which occur as result of this process are not permissible.

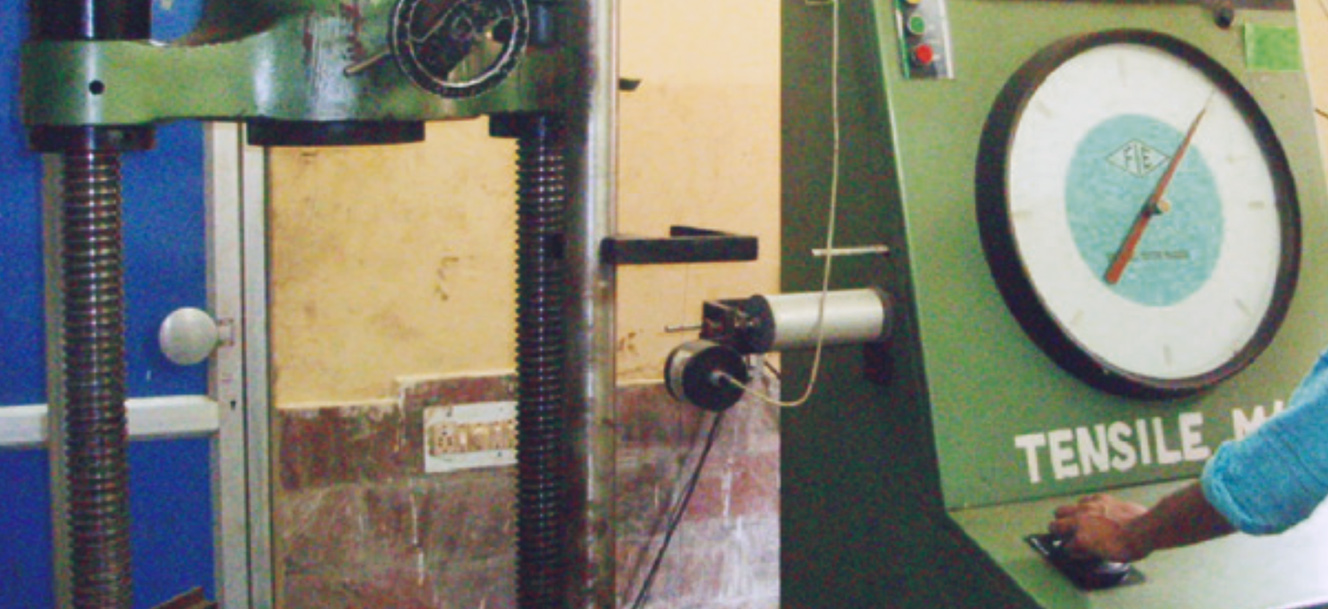

The tensile test specimen serves to determine the strength and ductility characteristics

i.e. yield strength, tensile strength and elongation. Tensile tests are normally carried

out at room temperature according DIN, ASTM, BS standards etc.

Flattening test mainly serves to detect microscopic internal and external flaws. It

involves compressing a tubular ring between two planes parallely placed to a

predetermined distance. Incipient cracks and internal or external defects which occur as

result of this process are not permissible. The flattening test is conducted as

described in ASTM A450 / ASTM A530 etc.

Samples from each lot are tested to ensure that the hardness of the tube is within

permissible limits.

This test ensures full ductility of the tubes, as well as tests the weld and the base

metal strength by stretching the material to its physical endurance limit.

HMTIPL's modern chemical laboratory is fully equipped to handle all chemical tests which

are used in pickling process and is also equipped for testing of chemical elements like

C, Ni, Si, Mo, Mn P, etc by specforiter.