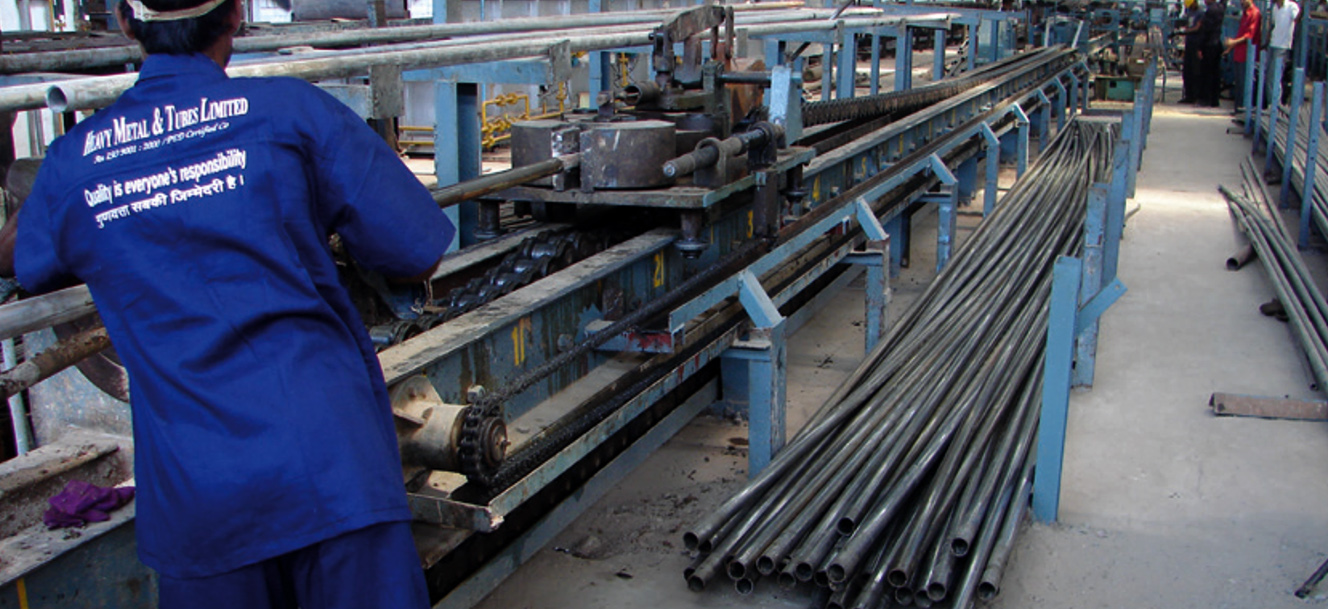

HMT has a dedicated plant of 13,500 sq. mtr. of covered area for manufacturing cold drawn of Carbon & Alloy Steel Tubes / pipes.

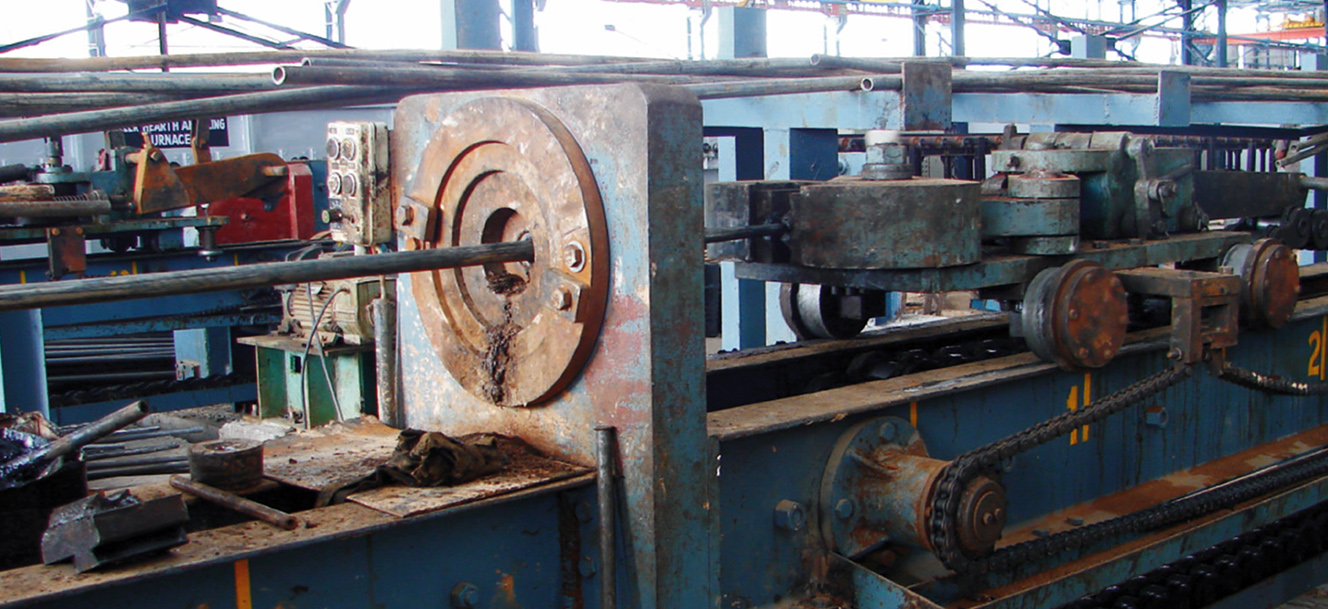

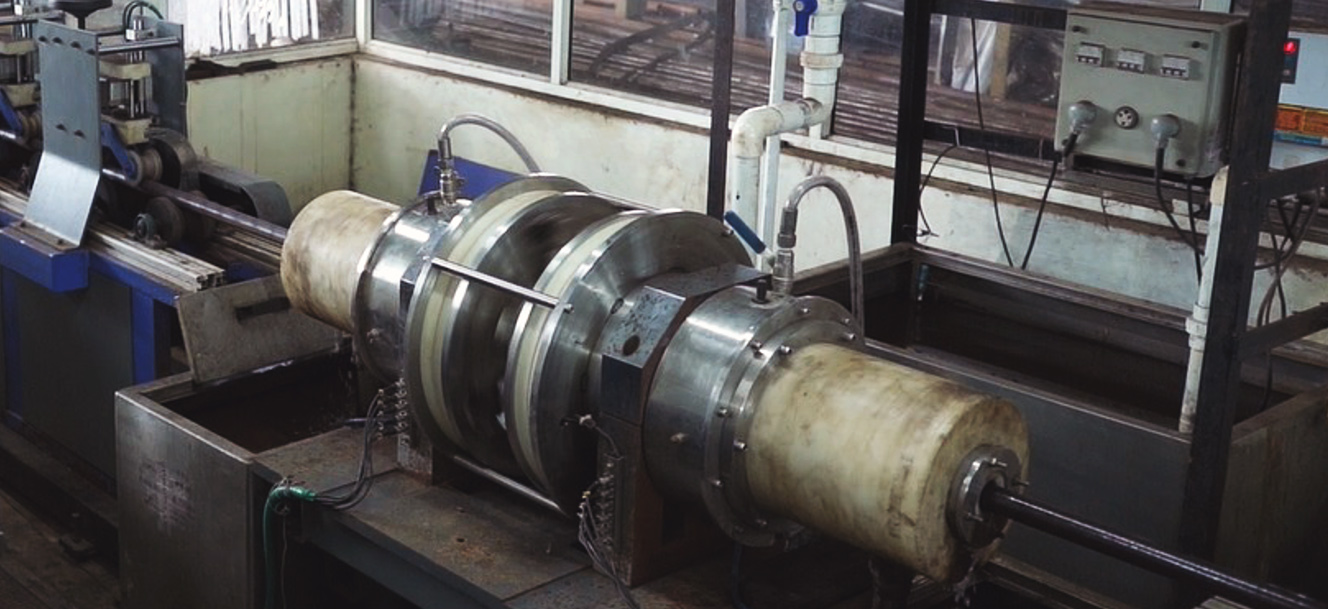

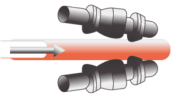

Cold finished Tubes / Pipes are produced out of quality seamless hollows produced in house in. Seamless hollows are either cold pilgered over pilger mills or drawn over draw benches using precision tooling (dies & plugs) to achieve perfect dimensions and smooth surfaces.

Drawn/pilgered tubes are subjected to heat treatment, straightening and surface treatment. Finished tubes / pipes undergo various testing as per the specification / customer's requirements followed by marking and packing.

| PRODUCTS |

|

|---|---|

| MANUFACTURING RANGE |

|

| GRADE & SPECIFICATIONS |

|

| CAPACITY |

|

Round Bar

Hot Finish Hollow

Preparation

Hollows / Mother Tubes

Surface Treatment

Cutting

Straightening

Heat Treatment

Drawing / Pilgering

Physical Chemical & Mockup Test

Non-Destructive Test

Destructive Test

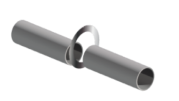

U Bending

(if required)

Surface Treatment

Final Cutting

Hydro Testing

Heat Treatment of U Bend Portion (If required)

Visual & Dimension Inspection

Marking

Packing

Marking, Packing & Dispatch